| Technically permissible total weight: | 14000 | [kg] |

| Permissible total weight: | 13660 | [kg] |

| Load capacity: | 10000 | [kg] |

| Empty weight: | 3660 | [kg] |

| Load volume: | 11.8 | [m 3] |

| Loading space: | 9.8 | [m 2] |

| Loading case inside lenght: | 4440 | [mm] |

| Loading case inside width: | trapez: 2190/2240 | [mm] |

| Overall dimensions (lenght/width/height): | 6154/2390/2579 | [mm] |

| Sidewall height: | 600+600 | [mm] |

| Floor/wall thickness: | 5/2,5 | [mm] |

| Platform height, measured from the ground: | 1320 | [mm] |

| Wheel track: | 1700 | [mm] |

| Suspension: | Leaf springs |

| Hitch-ring load: | 1880 | [kg] |

| Tyres: | 385/65 R22,5 (15R22,5) Regenerowane |

| Maximum speed: | 40 | [km/h] |

| Tipping system : | 3-side |

| Tipping cylinder (stroke / oil demand / pressure) | 1700/13L/200bar |

| Tractor power requirement: | 72,8/53,5 | [hp/kW] |

| Tipping angle (backwards/sides): | 50/46 | [˚] |

| Standard equipment | | |

| Loading case with universal system of opening walls | | |

| 3-side tipping system of the loading case with ball joints with the rear shock absorbers of optimum spacing | | |

| Selection of the direction of tipping by two pins protecting against incorrect handling | | |

| Trapezoid shape of the loading body (chest expands by 50 mm in the rearward direction) | | |

| Reinforced floor panel with central locking mechanism | | |

| Type of chassis: rectangular with closed profiles with fixed drawbar made of high resistant steel | | |

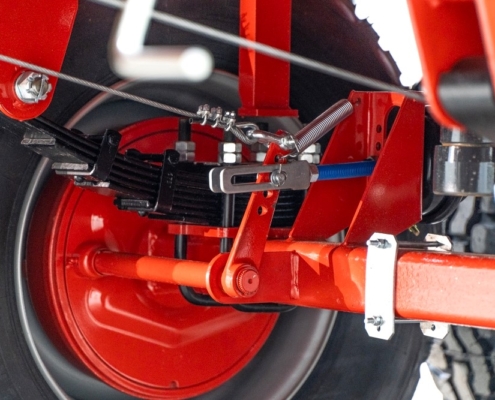

| Tandem suspension on 4 leaf springs, wheelbase 1160mm, fixed axles equipped with drum brakes | | |

| Axles 60 km/h | | |

| Universal fixed drawbar to connet with the lower or the upper hitch of the tractor | | |

| Drawbar towing hitch: rotary with ∅50 towing eye | | |

| Drawbar support: hydraulic scissor-type with movable leg and security hydraulic lock | | |

| Braking system: double pneumatic line | | |

| Crank hand brake | | |

| 12 V lighting system with rear electric socket | | |

| Rear lamps with protective grating | | |

| Coiled connecting cable lighting system | | |

| Hydraulic tipping system with cut-off valve | | |

| Tipping servo-motor of 3-side tipping system | | |

| Service support of the Tool box | | |

| Sidewalls and extensions made of profile PF600mm+600mm, 70 mm from the rim, with forged hinges and locks | | |

| Closed spaces of the sidewalls and extensions protected by laser weld | | |

| Sidewalls fastening string | | |

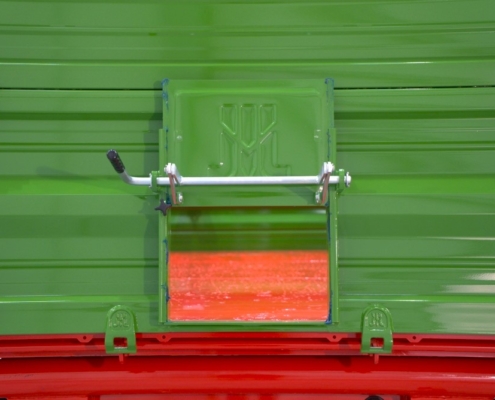

| Rear grain hatch with a lever in a rear wall | | |

| Rear mudguards | | |

| Wheel chocks + galvanized racks (2 pcs) | | |

| Double-component chemically hardened painting materials, UV-resistant | | |

| Tipping frame coulou: red RAL 3000 PRONAR | | |

| Sidewalls painting colour: green RAL 6010 PRONAR | | |

| Ladder and steps facilitating the access to the loading case | | |